- AS/RS

- Selective Pallet Racking

- China Radio Shuttle Rack

- Mezzanine Racking

- Steel Platform

- Cantilever Racking

- VNA Pallet Racking Series

- Drive In Racking Warehouse Series

- Carton Flow Racking

- Electric mobile shelving

- Medium Duty Shelving

- Non Standard Special Racking

- Logistic Equipment

- JN Factory:No.6 Xining Road, Jiangning District, Nanjing, China.

- JB Factory:NO.12-88, Qiaolin Industrial Park, Pukou District, Nanjing, China.

- 0086-25-89622571

- 0086-25-89622571

- 0086-25-89622573

- sale@sunnyrack.com

Push back racking

Push back racking renderings:

Product features:

1. The basic structure of push back racking is the same as the gravity shelf. On the basis of the dense arrangement and combination of the pallet racking, the track is laid on the beam, and the track has a certain slope. A longitudinal sliding trolley is set on the track, and the inbound and outbound ends are at the low end of the ramp.

2. Before warehousing, all trolley cars are automatically stacked at the outbound end of warehousing. When warehousing, the unit pallet goods are placed on the pallet truck, and the pallet goods after warehousing are pushed by the forklift before warehousing until the pallet goods are placed on the pallet truck below. When leaving the warehouse, take out the pallet goods at the entrance, and the trolley behind slides automatically to the position where the goods have been taken in front of the entrance.

3. The depth of push back racking is generally within the depth of 5 pallets, and the weight of unit goods is generally within 1500kg. Two cargo Spaces can be arranged on each row distance, and ordinary forklift can be used for operation.

4. The storage and withdrawal mode of push back racking is FILO. The storage and withdrawal of goods are carried out at the same end, with high work efficiency and space utilization rate, which is especially suitable for the storage of many varieties and small quantities of goods, it is widely used.

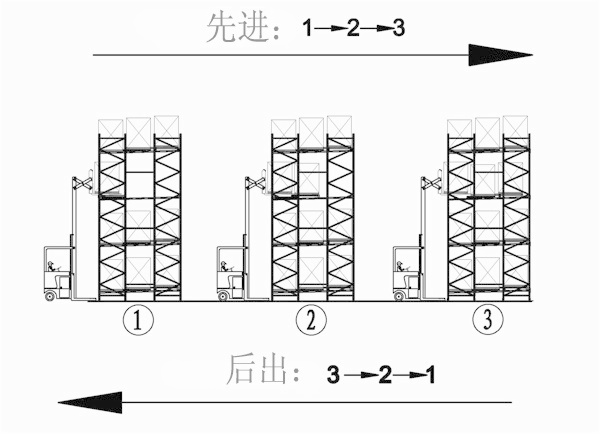

Operation mode FILO of push back racking: