- JN Factory:No.6 Xining Road, Jiangning District, Nanjing, China.

- JB Factory:NO.12-88, Qiaolin Industrial Park, Pukou District, Nanjing, China.

- 0086-25-89622571

- 0086-25-89622571

- 0086-25-89622573

- sale@sunnyrack.com

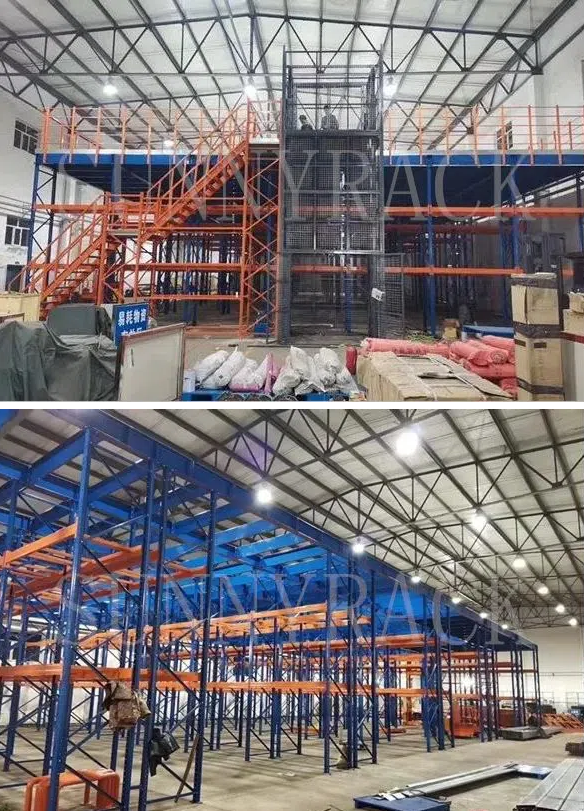

The Composition Characteristics Of Heavy-duty Mezzanine Rack And Purchase Considerations

2020.07.24Composition structure of heavy duty mezzanine rack

It uses heavy-duty shelf racks as the support of the main body and the floor slab use solid steel plate or solid steel checkered plate or perforated plate as the flooring. This type of system has many applications in the field of auto parts, auto 4S shops, light industry, electronics and other industries.

Usually equipped with stairs, hydraulic lifting platforms or elevators, or forklifts to transport goods upstairs. Installation and disassembly are convenient and flexible, and can be flexibly designed into two-story and three-story lofts according to the site and needs.

1. Fully assembled structure, free combination, movable, adjustable, removable, simple and flexible; multiple uses (office, production, service, storage);

2. The material section of the column, main beam and auxiliary beam is optimized, with strong bearing capacity and stable overall structure.

3. The surface is treated with electrostatic powder spraying, and the appearance is beautiful.

4. It can be flexibly designed as a two-story or multi-story building according to actual site needs. It is suitable for storing many kinds of goods and small batches of goods, making full use of space.

Soft reminders when purchase heavy duty mezzanine rack:

In terms of production:

From the selection of the tool holder to the stamping, the specifications must be very precise, and then the surface treatment is complete, and the processes such as rust prevention, electrostatic spraying and plastic spraying are complete. Some small factories are in order to reduce costs. ,

Warehouse site and shelf design:

1. The bearing weight and flatness of the floor. The bottom of the shelf should be firmly on the board, and the total weight of the shelf will be about a few tons, so the bearing capacity and flatness of the floor must be considered;

2. The lighting and fire protection facilities of the warehouse. The shelves are all designed in the warehouse, and the lighting facilities and fire boxes must be effectively avoided in order to design the shelf placement. In this way, the goods can be stored and stored well.

3. The specification of the goods and the reservation of the passage. The distance between the beams and the distance between the shelves should be designed according to the actual goods. The total height of the shelf is also closely related to the height, width, and weight of the goods. The distance between the shelves is commonly known as the shelf channel, which is the channel for forklifts and personnel to walk and access the goods. The design must be considered according to the actual situation;

4. The choice of forklift is also very important.