- JN Factory:No.6 Xining Road, Jiangning District, Nanjing, China.

- JB Factory:NO.12-88, Qiaolin Industrial Park, Pukou District, Nanjing, China.

- 0086-25-89622571

- 0086-25-89622573

- sale@sunnyrack.com

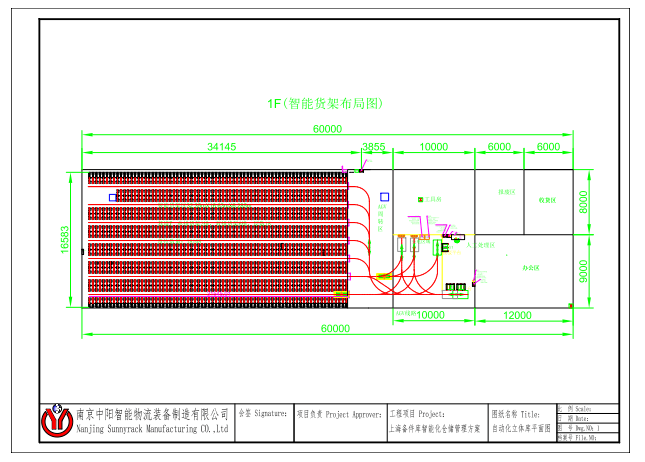

LGV System project case of Shanghai Volkswagen Automatic storage and retrieval system

Customer name: Shanghai Volkswagen

Industry involved: Automobile industry

Racking type: automatic storage and retrieval system AS/RS

Project Overview:

In early June 2020, Nanjing SUNNYRACK joined hands with Shanghai Volkswagen Automobile Co., LTD to successfully build a systematic, digital and intelligent warehouse storage system, and the project has recently completed the acceptance and inspection work.

The total area of the Volkswagen spare parts warehouse is about 3,000 square meters. The layout of the intelligent racking area is 80.5m in length, 37.3m in width and 6.8m in height. The automatic access to unit cargo boxes is realized by the fork plate handling trolley, namely LGV system. The warehouse has 18,108 storage Spaces, including 7 lanes, 18 rackings, 2 charging cabinets, 2 connecting platforms and 4 LGV laser-guided fork plate handling vehicles.

Automatic storage and retrieval system -- LGV system:

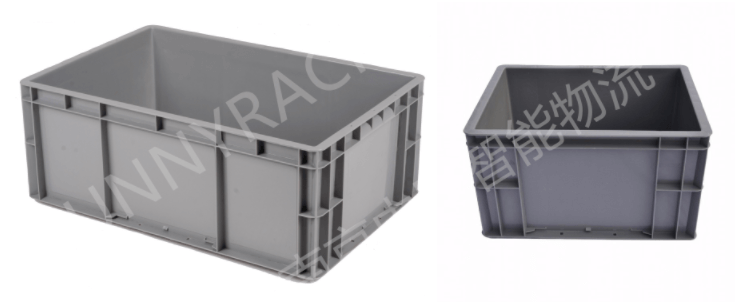

The main body of LGV system of automatic storage and retrieval system is composed of racking, laser guided fork plate handling trolley, plastic part box, in-and-out work table and operation control system. The racking as a whole is a combination of steel structure, the racking is the standard plastic part box size cargo space. According to the instructions issued by the operating system, the forklift trolley is guided by laser through the roadway between the shelves to complete the work of stoaging and picking up plastic box.

1. racking: steel structure used for storing goods, combined racking structure. This project is different from ordinary stacker-type automatic storage and retrieval system project, LGV has very high requirements on the production and installation accuracy of the racking as a whole: (1) the vertical deviation of the racking uprights after loading along the length and width of the lanes is <3mm, and the vertical deviation between the uprights and the installation ground is <3mm; (2) Rack uprights total height error ≤2mm, hole distance cumulative error ≤2mm; (3) the length error of the racking load cantilever plate is ≤ 1mm, and the deflection after the cantilever is fully loaded is < L/400; The height deviation of adjacent cantilever plates on the same floor is ≤2mm, and the height deviation of cantilever plates on the same floor along the direction of lanes is < 3mm; The height error of both ends of cantilever plate after assembly is ≤ 2mm;

Plastic part box: a device for carrying parts (goods), also known as a workstation appliance.

2. LGV forklift trolley size 1450*530*1550mm, laser guidance.

3.WCS automatic control system: it is the automatic control system that drives the equipment of automatic storage and retrieval system. The main control mode is using fieldbus.

4.WMS information management system: it is the core of the fully automated storage and retrieval system and can be networked or integrated with other systems (such as ERP system).

Advantages of automatic storage and retrieval system -LGV system:

Improve warehouse utilization and operation efficiency

Taking full advantage of the vertical space of the warehouse, the storage capacity per unit area is much larger than that of the traditional warehouse. In addition, compared to traditional automatic storage and retrieval system (stacker or mother-and-child vehicles), items must be classified and deposited in big pallet or plastic basket, It is not conducive to storage and selection of small and micro goods (accessories), resulting in the unit cargo compartment space idle, the LGV forklift trolley with small plastic parts box can access little tiny goods (accessories) in random, the system automatically records accurate position, Greatly improve the utilization rate of space.